Streamlining Manufacturing and Logistics for Maximum Efficiency

In today's fast-paced and highly competitive business landscape, manufacturing and logistics providers must optimize their operations to achieve maximum efficiency. This involves producing goods swiftly and cost-effectively while ensuring timely delivery to customers. Achieving this balance is crucial for maintaining profitability and competitive advantage.

Understanding the Importance of Efficiency in Manufacturing and Logistics

Efficiency in manufacturing and logistics directly impacts a company's bottom line. Streamlined operations lead to reduced costs, increased profits, and a stronger position against competitors. Additionally, efficient processes enhance customer satisfaction, which is vital in a customer-centric marketplace.

- Cost Reduction: Minimizing waste and optimizing resources lowers operational expenses.

- Profit Maximization: Increased productivity leads to higher output and revenue.

- Competitive Edge: Efficient operations enable faster response to market changes.

- Customer Satisfaction: Timely deliveries and quality products boost customer loyalty.

According to a 2023 Industry Report by ShipScience, companies that focus on operational efficiency experience a 20% increase in profitability.

Key Challenges in Streamlining Operations

Manufacturers and logistics providers encounter several challenges when aiming to streamline their operations:

Supply Chain Disruptions

Unexpected events like natural disasters or geopolitical tensions can disrupt supply chains, leading to delays and increased costs.

Inventory Management

Balancing inventory levels to meet demand without overstocking is a persistent challenge.

Technological Adaptation

Keeping up with rapidly evolving technology requires significant investment and skilled personnel.

Sustainability Demands

The growing emphasis on eco-friendly practices pressures companies to adopt sustainable operations, often at higher initial costs.

Addressing these challenges requires a comprehensive and adaptable approach, leveraging technology and best practices to mitigate risks and enhance efficiency.

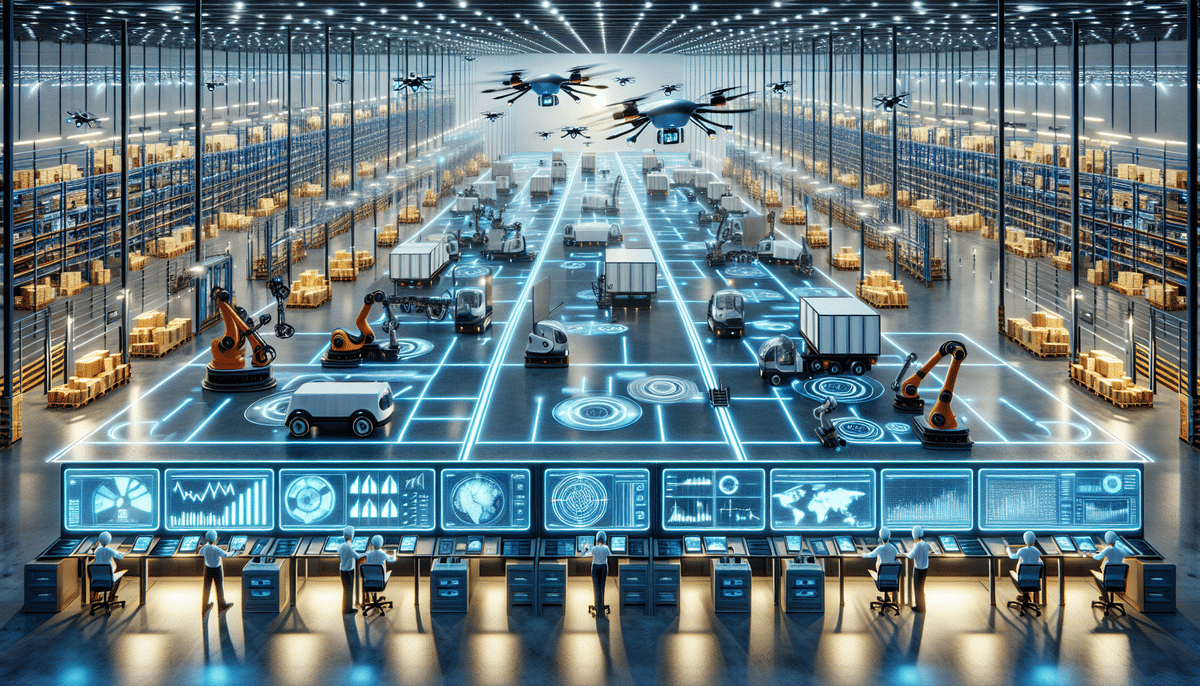

The Role of Automation and Technology

Incorporating automation and advanced technologies is pivotal in enhancing efficiency within manufacturing and logistics:

Automation in Operations

Automated systems reduce human error and increase productivity by handling repetitive tasks such as inventory management, order processing, and shipping.

Data Analytics

Utilizing data analytics provides actionable insights into operational performance, enabling informed decision-making and continuous improvement.

Internet of Things (IoT)

IoT devices enhance supply chain visibility by enabling real-time tracking of inventory and shipments, facilitating proactive management of potential disruptions.

According to ShipScience's 2023 Technology Trends Report, companies implementing automation have seen a 15% increase in operational efficiency.

Implementing Lean Manufacturing and Logistics Systems

A lean approach focuses on minimizing waste, optimizing processes, and improving quality:

Principles of Lean Manufacturing

Lean manufacturing emphasizes value creation for the customer with fewer resources by eliminating non-value-added activities.

Benefits of Lean Logistics

Applying lean principles to logistics enhances efficiency, reduces costs, and improves delivery times.

Continuous Improvement

Lean systems foster a culture of ongoing assessment and refinement, ensuring sustained operational excellence.

Businesses adopting lean methodologies report up to a 25% reduction in operational costs, as highlighted in the ShipScience Success Stories.

Enhancing Supply Chain and Inventory Management

Optimizing supply chain and inventory management is essential for efficient operations:

Supply Chain Visibility

Enhanced visibility through technology allows for better tracking of materials and products, reducing delays and shortages.

Inventory Optimization

Techniques such as just-in-time inventory and demand forecasting help maintain optimal inventory levels, minimizing holding costs and stockouts.

Sustainable Supply Chain Practices

Integrating sustainability into the supply chain not only reduces environmental impact but also meets consumer demand for eco-friendly products.

Statistics from the 2023 Supply Chain Report indicate that companies with optimized supply chains achieve a 30% improvement in delivery performance.

Fostering Continuous Improvement and Reducing Waste

Continuous improvement and waste reduction are cornerstones of efficient manufacturing and logistics:

Kaizen and Six Sigma

Adopting methodologies like Kaizen and Six Sigma helps identify and eliminate waste, improving process efficiency and quality.

Closed-Loop Systems

Implementing closed-loop systems ensures materials are reused or recycled, reducing waste and lowering costs.

Employee Engagement

Encouraging employee participation in improvement initiatives fosters a proactive culture focused on enhancing operations.

Research published by ShipScience shows that companies practicing continuous improvement see a 35% boost in overall operational efficiency.

Measuring Performance and Case Studies

Monitoring key performance metrics is vital to assess the effectiveness of efficiency initiatives:

Key Performance Indicators (KPIs)

Metrics such as cycle time, lead time, inventory turnover, and customer satisfaction provide insights into operational performance.

Performance Tracking

Regularly tracking KPIs helps identify areas for improvement and ensures that efficiency gains are sustained over time.

Real-World Success Stories

Examining case studies of companies that have successfully streamlined their manufacturing and logistics operations offers valuable lessons and best practices.

For example, a case study featured on ShipScience's Case Studies page highlights how a leading manufacturer reduced their lead time by 40% through strategic process optimization and technology integration.

Overcoming Resistance to Change

Implementing efficiency improvements often faces resistance from within the organization:

Addressing Employee Concerns

Communicating the benefits of changes and involving employees in the process can alleviate fears related to job security and process alterations.

Training and Support

Providing adequate training and resources ensures that employees are well-equipped to adapt to new systems and processes.

Leadership and Vision

Strong leadership that clearly articulates the vision and objectives of efficiency initiatives fosters a supportive environment for change.

According to ShipScience's Change Management Guide, organizations that effectively manage resistance to change experience smoother transitions and achieve their efficiency goals more effectively.

Conclusion

Streamlining manufacturing and logistics operations is essential for businesses to remain competitive in today’s dynamic market. By adopting best practices, leveraging automation and technology, and fostering a culture of continuous improvement, companies can optimize their operations, reduce costs, and enhance customer satisfaction. Embracing these strategies not only leads to operational excellence but also positions businesses for sustainable growth and success.