Box dimensions may seem like a simple concept, but they come in various types and units of measurement that can be confusing to understand. If you are not familiar with the proper way to measure and interpret box dimensions, you may end up with boxes that do not meet your needs or shipping requirements, resulting in damage or additional costs. That is why it is essential to learn how to read box dimensions correctly. In this guide, we will explain why understanding box dimensions is important, the different types of box dimensions to consider, measuring and calculating box dimensions, common mistakes to avoid when reading box dimensions, interpreting labels, and much more.

Importance of Understanding Box Dimensions

Understanding box dimensions is crucial to ensure that your shipped items are well-protected and arrive at their destination in one piece. The dimensions of a box help determine the amount of packaging material required, the shipping costs, and whether the item fits properly in the box. Knowing how to read box dimensions can also help you choose the right box size, avoid additional costs, and reduce shipping hazards.

Additionally, understanding box dimensions can help optimize your storage space. By selecting boxes that are the right size for your items, you can maximize the use of your storage area and reduce clutter. This is especially important for businesses that need to store large quantities of inventory or for individuals with limited storage space in their homes.

Types of Box Dimensions

Interior and Exterior Dimensions

The interior dimensions are the length, width, and height of the box's interior space. In contrast, the exterior dimensions include the length, height, and width of the outer box, accounting for the thickness of the walls. Understanding both is essential for ensuring your items fit and for accurate shipping calculations.

Shipping Dimensions and Dimensional Weight

Shipping dimensions refer to the total size of the box, including any overhangs or protruding features like handles or slots. These factors can impact shipping costs significantly. The dimensional weight is a measure that takes into account both the size and the weight of the package, and shipping carriers use this metric to calculate shipping fees. For example, if a box has large dimensions but is lightweight, the dimensional weight may result in higher shipping costs.

Weight Capacity

The weight capacity of a box indicates the maximum weight it can hold without breaking or collapsing. Choosing a box with the appropriate weight capacity is crucial to protect your items during shipping or storage. Some boxes come with reinforced walls or corners to provide extra strength and durability, which is beneficial for heavier items or for boxes that will be stacked or transported frequently.

Measuring Box Dimensions Accurately

Measuring Length, Width, and Height

To measure a box's length, width, and height accurately, use a ruler, measuring tape, or caliper. Measure either the interior or exterior dimensions depending on your needs. Ensure you measure to the nearest eighth of an inch or millimeter for precision. For rectangular boxes, measure each side and multiply the numbers to calculate the cubic volume of the box.

Handling Irregular Shapes

For irregularly shaped boxes, such as cylinders or spheres, measuring requires different approaches. For a cylinder, measure the diameter of the circular base and the height, then use the formula V = πr²h to calculate the volume. For a sphere, measure the diameter and use the formula V = 4/3πr³.

Units of Measurement

Box dimensions can be measured in various units, including inches, feet, centimeters, and meters. It's essential to use consistent units throughout the measurement process to avoid errors. Most shipping carriers use the imperial system (inches and cubic feet), but some may use the metric system (centimeters and cubic meters). Be sure to convert measurements to the appropriate system before sending your package.

Common Mistakes and How to Avoid Them

Confusing Interior and Exterior Dimensions

A common mistake is mixing up interior and exterior dimensions, which can lead to miscalculations, additional costs, or damage to your items. Always double-check which dimensions you are using for your calculations.

Overloading Boxes

Exceeding a box's weight capacity can cause it to break or collapse, resulting in damaged items or injury to handlers. Always adhere to the weight limits specified for each box.

Assuming All Boxes Are Equal

Different types of boxes have varying strengths and are suited for different purposes. For example, corrugated boxes are ideal for heavy items, while folding cartons are better for lightweight items. Choose the right type of box based on the specific needs of your shipment or storage.

Choosing the Right Box for Your Needs

Size and Fit

Select a box that fits your item snugly to minimize movement during transport. This reduces the risk of damage and may lower shipping costs.

Weight Considerations

Consider both the actual weight and the dimensional weight when selecting a box. Choosing the right size can help avoid unnecessary shipping fees.

Fragility of Items

For fragile items, opt for boxes with extra padding or cushioning materials. Reinforced boxes can provide additional protection during transit.

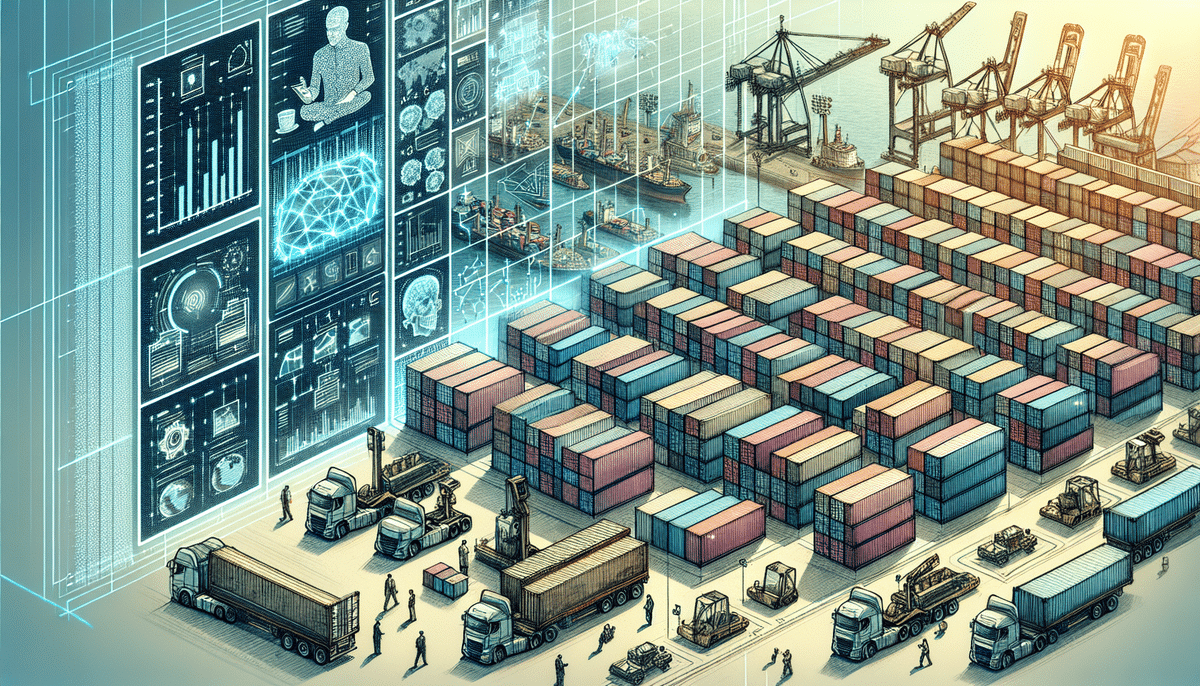

The Impact of Box Dimensions on Shipping and Storage

Shipping Costs

The dimensions of a box significantly affect shipping costs. Larger boxes with higher dimensional weight often incur higher fees. Understanding how carriers calculate these costs can help you choose the most cost-effective box size.

Storage Optimization

Properly sized boxes can maximize storage space and improve organization. Use shelving systems or pallets to store boxes efficiently based on their dimensions.

Packaging Design

Effective packaging design minimizes movement within the box and provides adequate protection. Using dividers or partitions can enhance the efficiency of your packaging, ensuring items remain secure during transit.

Future Trends in Box Dimension Standards

The standards for box dimensions are evolving to meet the changing needs of the shipping industry. Future updates may include more specific size requirements and advanced guidelines for calculating dimensional weight. Staying informed about these changes will help businesses adapt and maintain cost-effective shipping practices.

In conclusion, learning how to read box dimensions is a crucial skill that can help you choose the right-sized box, minimize additional costs, and ensure that your items arrive safely. By following the steps in this guide, you can avoid common mistakes, accurately measure box dimensions, and choose the most efficient packaging design to fit your needs. Remember to store and organize boxes by their dimensions, and stay updated on the latest industry trends and standards for box dimensions.