Introduction to CBM (Cubic Meter) Measurement

Cubic meter (CBM) measurement is the calculation of the volume of an object or space in cubic meters. It is widely utilized in the shipping and logistics industry, as well as in trade and commerce globally. This article provides a comprehensive guide to understanding CBM measurement, including its history, evolution, methods of calculation, and applications across various industries.

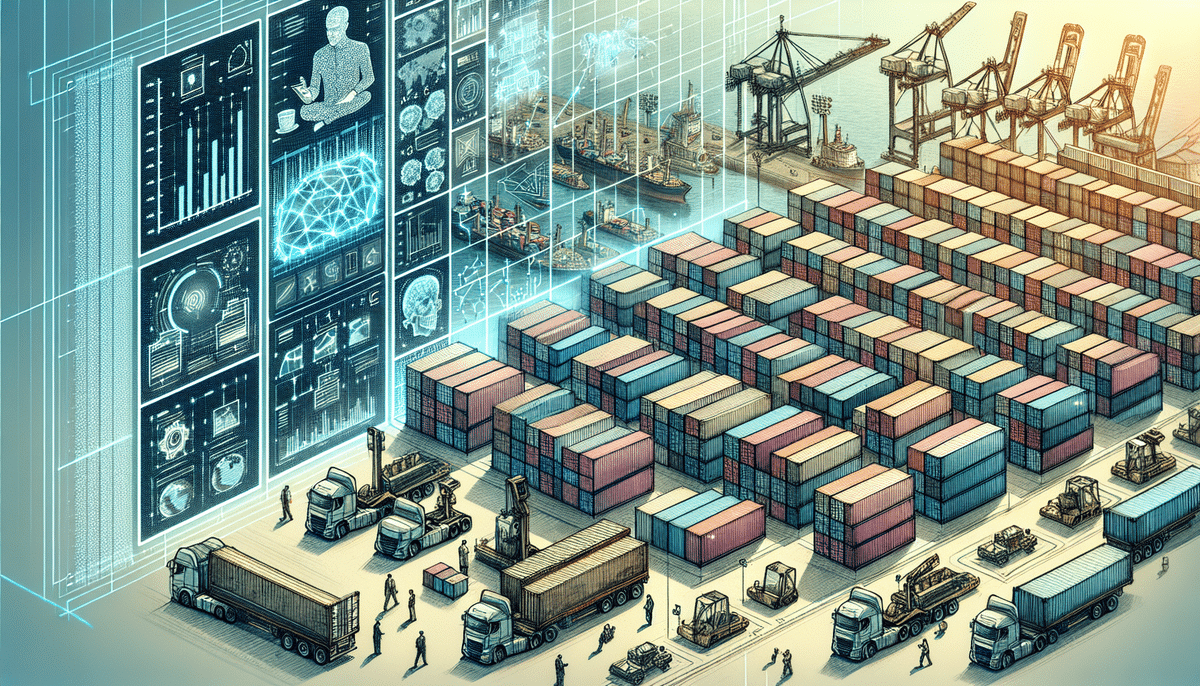

The Importance of CBM in Shipping and Logistics

CBM measurement is crucial in the shipping and logistics industry because it directly influences freight rates. Freight rates are often calculated based on the volume of cargo being shipped, measured in CBM. For instance, according to the Statista report, global container shipping revenue reached over $112 billion in 2022, underscoring the significance of accurate CBM measurements.

Accurate CBM measurement allows shipping companies to optimize space utilization within containers and cargo holds, leading to cost efficiencies and enhanced operational effectiveness.

Moreover, CBM measurement plays a vital role in ensuring the safety of cargo during transit. By precisely gauging the volume of cargo, companies can ensure appropriate securing and even weight distribution, minimizing the risk of accidents and damage.

Additionally, CBM is essential for customs clearance. Many countries impose regulations on the maximum volume of cargo that can be imported or exported. Accurate CBM measurement ensures compliance, preventing potential delays, fines, or cargo seizures. For more information on customs regulations, refer to the U.S. Customs and Border Protection.

Historical Evolution of CBM Measurement

The concept of volume measurement dates back to ancient civilizations, including the Greeks, who utilized basic volume calculations for construction and engineering purposes. The application of CBM measurement within the shipping and logistics industries began to gain prominence in the 19th century, coinciding with the advent of the steamship and the standardization of container sizes.

The standardization of container dimensions revolutionized global trade, facilitating efficient handling and transportation of goods. This led to CBM becoming a standard unit of measurement within the industry.

In recent decades, technological advancements have enhanced the accuracy and efficiency of CBM measurement. Innovations such as laser scanning and 3D modeling allow for precise measurement of irregularly shaped objects and containers, further expanding the applications of CBM across various sectors. According to the 3D Scan Store, these technologies have significantly reduced measurement errors and improved operational workflows.

Methods of Calculating CBM

There are several methods for calculating CBM, each suited to different types of cargo and industry requirements:

- CBM Formula: The most common method involves multiplying the length, width, and height of the object or space in meters. CBM = Length (m) × Width (m) × Height (m).

- Displacement Method: Used primarily in the marine industry, this method calculates the volume of a submerged object by measuring the amount of water displaced.

- Load Factor Method: This method accounts for irregularly shaped or stacked cargo by applying a load factor to the measured volume.

- Weight Method: Involves measuring the weight of an object and dividing it by its density to determine volume. This is common in the transportation industry but is not suitable for irregular shapes.

Choosing the appropriate CBM calculation method depends on the nature of the cargo and the specific requirements of the industry. For example, the load factor method is ideal for optimizing space in containerized shipping, while the displacement method is essential for assessing the volumetric impact of vessels in the marine industry.

It is critical to use precise measuring tools and techniques to ensure the accuracy of CBM calculations. Advanced technologies like 3D scanning and automated measurement systems can significantly enhance measurement precision and reliability, as highlighted by the International Maritime Organization.

Applications of CBM in Various Industries

CBM measurement is employed across a diverse range of industries, each leveraging its utility in unique ways:

- Shipping and Transportation: Used to calculate freight rates and optimize cargo space within containers and transport vehicles.

- Construction: Determines the volume of materials such as concrete and soil required for projects.

- Manufacturing: Helps in calculating raw material requirements and optimizing warehouse storage.

- Healthcare: Measures the volume of medical equipment and supplies, and calculates medication dosages based on patient profiles.

- Mining and Agriculture: Utilized for inventory management and transportation planning of bulk materials.

In each of these sectors, CBM serves as an essential tool for enhancing operational efficiency, ensuring resource optimization, and maintaining cost-effectiveness.

The Advantages of Using CBM for Shipping and Transporting Goods

Utilizing CBM measurement in shipping and transportation confers several advantages:

- Optimized Space Utilization: Ensures efficient use of container and vehicle space, reducing wasted volume and lowering transportation costs.

- Accurate Pricing: Facilitates precise freight rate calculations, benefiting both shippers and recipients through transparent and fair pricing.

- Improved Logistics Planning: Allows for effective route and transportation mode selection, reducing transit times and enhancing delivery performance.

- Enhanced Cargo Security: Ensures cargo is properly secured and weight distribution is balanced, minimizing the risk of damage during transport.

- Environmental Sustainability: Optimizing cargo space can lead to fewer transport vehicles being required, thereby reducing carbon emissions.

Overall, CBM measurement contributes to increased profitability and operational efficiency within the shipping and logistics sectors.

Ensuring Accuracy in CBM Measurement

Accurately measuring CBM is essential for optimizing logistics and avoiding costly errors. Here are some best practices:

- Use Precise Measurement Tools: Employ high-quality measuring devices such as laser meters or digital measuring systems to obtain accurate dimensions.

- Double-Check Measurements: Take multiple measurements and calculate the average to enhance accuracy.

- Consistent Units of Measurement: Ensure all measurements are in the same unit (meters) to prevent calculation errors.

- Account for Irregular Shapes: Use 3D modeling or specialized formulas to measure objects that do not conform to standard geometric shapes.

- Training: Ensure personnel responsible for measuring are adequately trained in CBM calculation techniques and protocols.

Implementing these practices can significantly improve the reliability of CBM measurements, thereby enhancing overall logistics efficiency. For further reading on best practices, visit Logistics Management.

Common Mistakes to Avoid When Measuring CBM

Accurate CBM measurement is critical, yet common mistakes can lead to significant issues. Here are some pitfalls to avoid:

- Incorrect Formula Usage: Applying the wrong formula or mathematical method can result in inaccurate volume calculations.

- Inaccurate Measurements: Poor measuring techniques or tools can distort the dimensions collected, leading to calculation errors.

- Neglecting Protrusions or Indentations: Failing to account for irregular features of an object can skew the overall CBM.

- Mixing Measurement Units: Using different units (meters, centimeters, feet) within the same calculation process can cause inconsistencies and errors.

- Ignoring Cargo Securing: Overlooking the need to adjust CBM calculations based on how cargo is secured within a container may lead to inefficient space utilization.

By recognizing and addressing these common mistakes, businesses can ensure more accurate CBM measurements, leading to enhanced operational efficiency and cost savings.

The Future of CBM Measurement: Trends and Innovations

The landscape of CBM measurement is evolving with technological advancements and industry demands shaping its future. Key trends and innovations include:

- Digital Measurement Technologies: Adoption of digital tools such as laser scanning and 3D imaging is enhancing measurement precision and speed.

- Integration with IoT: Internet of Things (IoT) devices are being used to monitor and record volume measurements in real-time, providing data analytics for optimizing logistics.

- Machine Learning and AI: Artificial intelligence algorithms are being developed to automate CBM calculations, identify patterns, and predict optimal cargo arrangements.

- Standardization Efforts: Ongoing efforts to standardize CBM measurement protocols across industries are facilitating consistency and interoperability in global trade.

- Blockchain Technology: Utilization of blockchain for secure and transparent documentation of CBM measurements, enhancing trust and traceability in the supply chain.

These innovations are set to drive the precision, efficiency, and reliability of CBM measurement, further cementing its role in the global logistics framework. For insights into future trends, refer to the World Economic Forum.

Comparison Between Cubic Meter and Other Measurement Systems

CBM measurement is often compared to other volume measurement systems, such as cubic feet and liters. While these systems differ in units, the underlying concept of volume calculation remains consistent.

- Cubic Meter (CBM): Primarily used internationally, especially in logistics and shipping, representing volume in meters cubed.

- Cubic Feet: Commonly used in the United States for volume measurements, particularly in construction and manufacturing.

- Liters: Utilized in contexts requiring smaller volume units, such as in healthcare for medication dosages.

Conversion between these systems is straightforward, but it is essential to use the appropriate measurement system based on regional standards and industry practices to ensure consistency and accuracy in volume calculations.

Example Conversion: 1 CBM = 35.315 cubic feet. Therefore, to convert CBM to cubic feet, multiply by 35.315.

Understanding the differences and conversion rates between these measurement systems is critical for international trade and multi-region logistics operations. For detailed conversion tables, visit the National Institute of Standards and Technology.

Conclusion

CBM measurement is a fundamental aspect of the shipping and logistics industries, serving as a key determinant of freight rates, cargo safety, and operational efficiency. This comprehensive guide has explored the basics of CBM, its historical evolution, various calculation methods, and its diverse applications across multiple industries.

By adhering to best practices for accurate CBM measurement and avoiding common errors, businesses can optimize their logistics operations, reduce costs, and enhance overall profitability. Looking ahead, technological innovations and standardization efforts are set to further improve the precision and efficiency of CBM measurement, solidifying its indispensable role in global trade and commerce.

Understanding and effectively managing CBM measurement is essential for stakeholders across the supply chain, ensuring seamless and efficient movement of goods worldwide.