Streamlining Manufacturing Logistics for Improved Efficiency

The manufacturing industry thrives on the ability to produce high-quality products efficiently and cost-effectively. Achieving this requires a well-orchestrated logistics system that seamlessly integrates various processes and systems. This article delves into strategies manufacturers can employ to optimize their logistics processes, enhance efficiency, reduce costs, and ultimately boost profits.

Understanding the Fundamentals of Manufacturing Logistics

Logistics is the backbone of any manufacturing operation, encompassing the planning, implementation, and control of the flow of materials, products, and information throughout the supply chain. Key components include:

- Raw Materials Procurement: Ensuring timely and cost-effective acquisition of necessary materials.

- Inventory Management: Balancing inventory levels to prevent excess or shortages.

- Transportation and Distribution: Efficiently moving products from one location to another.

- Customer Service: Maintaining high levels of customer satisfaction through reliable logistics.

Effective manufacturing logistics ensures that the right materials are available in the right quantities at the right time and place. Utilizing tools like Just-In-Time (JIT) inventory and lean manufacturing principles helps achieve this balance by minimizing waste and optimizing processes.

Overcoming Common Challenges in Manufacturing Logistics

Despite its importance, many manufacturers face significant challenges in managing their logistics effectively:

- Poor Inventory Management: Leads to either excess stock or stockouts, affecting cash flow and production schedules.

- Inaccurate Demand Forecasting: Results in mismatches between supply and demand.

- Inefficient Transportation Systems: Causes delays and increased costs.

- Inadequate Communication: Hinders coordination between stakeholders.

To address these issues, manufacturers can implement strategies such as:

- Adopting lean manufacturing techniques to streamline operations.

- Investing in advanced technologies like warehouse management systems and GPS tracking.

- Establishing clear communication channels with all parties involved.

Enhancing supply chain visibility through real-time data tools can also help manufacturers make informed decisions and swiftly address any disruptions.

Implementing Lean Manufacturing and Process Optimization

Lean manufacturing focuses on minimizing waste and maximizing efficiency, offering numerous benefits for logistics:

- Reduced Production Time: Streamlined processes lead to faster turnaround.

- Cost Savings: Less waste translates to lower operational costs.

- Enhanced Quality: Continuous improvement practices ensure higher product standards.

Key strategies include:

- Optimizing Warehouse Layout: Efficient space utilization speeds up material handling.

- Reducing Inventory Levels: Implementing JIT inventory systems to decrease holding costs.

- Improving Transportation Management: Enhancing route planning to reduce delivery times.

Continuous improvement, or Kaizen, involves regularly analyzing and refining processes to maintain high efficiency and adaptability to changing market demands.

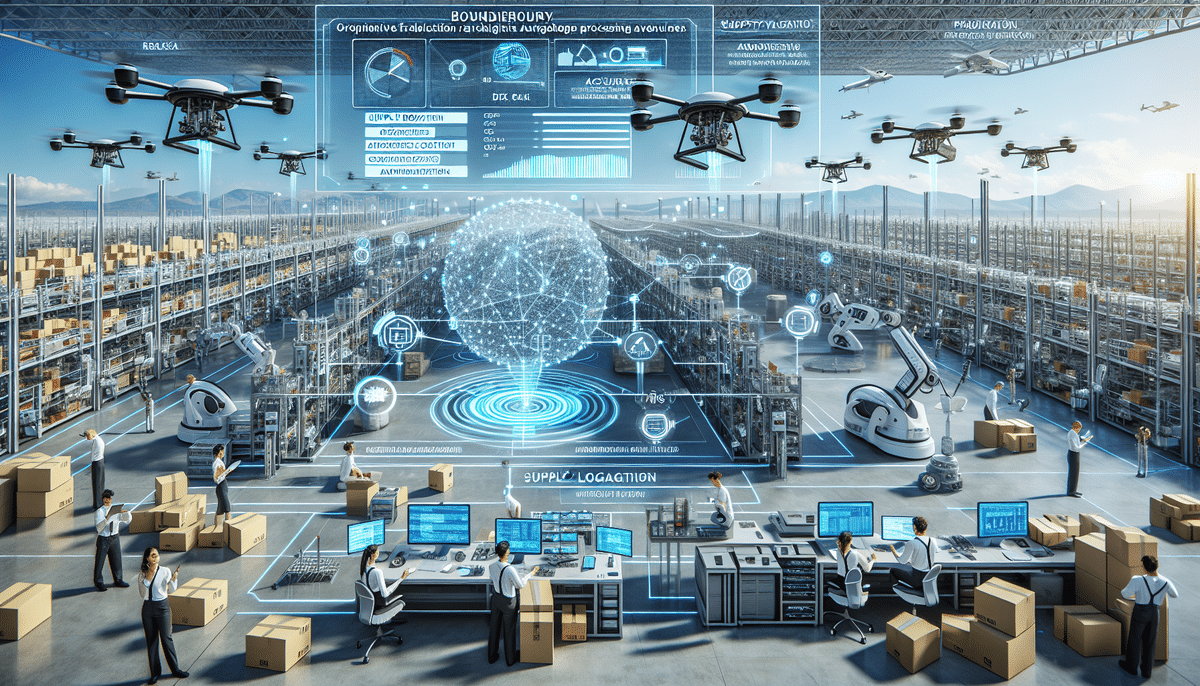

Leveraging Technology to Enhance Logistics

Modern technology plays a pivotal role in optimizing manufacturing logistics:

- Warehouse Management Systems (WMS): Automate inventory tracking and order fulfillment.

- Transportation Management Software (TMS): Optimizes routing and reduces transportation costs.

- RFID Tagging and IoT Sensors: Provide real-time visibility into inventory levels and shipment status.

- Artificial Intelligence (AI): Analyzes data to predict demand trends and optimize supply chain performance.

Integrating these technologies can provide manufacturers with a competitive edge by enhancing efficiency, reducing errors, and enabling data-driven decision-making. For instance, AI-driven demand forecasting can significantly improve accuracy, reducing the risk of overproduction or stockouts.

Sustainable and Integrated Supply Chain Management

As sustainability becomes a critical focus, manufacturers are increasingly adopting eco-friendly logistics practices:

- Reducing Packaging Waste: Utilizing recyclable and minimal packaging materials.

- Using Renewable Energy Sources: Powering logistics operations with sustainable energy.

- Optimizing Transportation Routes: Minimizing fuel consumption and emissions.

Integrating supply chain operations through systems like Enterprise Resource Planning (ERP) ensures a seamless flow of information and materials. Collaborative Planning, Forecasting, and Replenishment (CPFR) encourages cooperation between suppliers and customers, enhancing overall supply chain efficiency.

Implementing a closed-loop supply chain, where products and materials are reused or recycled, not only reduces environmental impact but also lowers costs associated with waste management.

Measuring Success with Key Performance Indicators

Tracking the right Key Performance Indicators (KPIs) is essential for assessing the effectiveness of logistics optimization efforts:

- Inventory Turnover: Measures how often inventory is sold and replaced over a period.

- On-Time Delivery Rates: Assesses the reliability of the delivery process.

- Order Fulfillment Rates: Indicates the ability to meet customer orders accurately and promptly.

- Transportation Costs: Tracks expenses related to moving goods.

- Customer Satisfaction: Gauges the effectiveness of logistics in meeting customer expectations.

By continuously monitoring these KPIs, manufacturers can identify areas for improvement, make informed decisions, and ensure that their logistics operations contribute positively to the overall business objectives.

Empowering Teams and Selecting the Right Partners

The human element is crucial in ensuring efficient logistics operations. Empowering teams involves:

- Providing Training: Ensuring that staff are well-versed in the latest logistics practices and technologies.

- Offering the Right Tools: Equipping teams with the necessary resources to perform their roles effectively.

- Fostering a Culture of Continuous Improvement: Encouraging teams to seek out and implement improvements.

Selecting the right logistics partner is equally important. Factors to consider include:

- Industry Experience: Partners with a strong track record in your specific industry.

- Technological Capabilities: Advanced systems and tools that align with your logistics needs.

- Customer Service and Communication: Effective and transparent communication channels.

Choosing a reliable logistics partner can enhance your supply chain's efficiency and help you navigate complex logistics challenges with ease.

Conclusion

Optimizing manufacturing logistics is a multifaceted endeavor that requires careful planning, the right strategies, and continuous improvement. By understanding the fundamentals, overcoming common challenges, implementing lean manufacturing principles, leveraging advanced technologies, committing to sustainability, measuring success through KPIs, and empowering your team, you can create a logistics system that is efficient, cost-effective, and responsive to market demands. Embracing these practices will position your manufacturing business for sustained success in a competitive landscape.