Introduction to Warehouse Automation: Locus Robotics vs. AutoStore

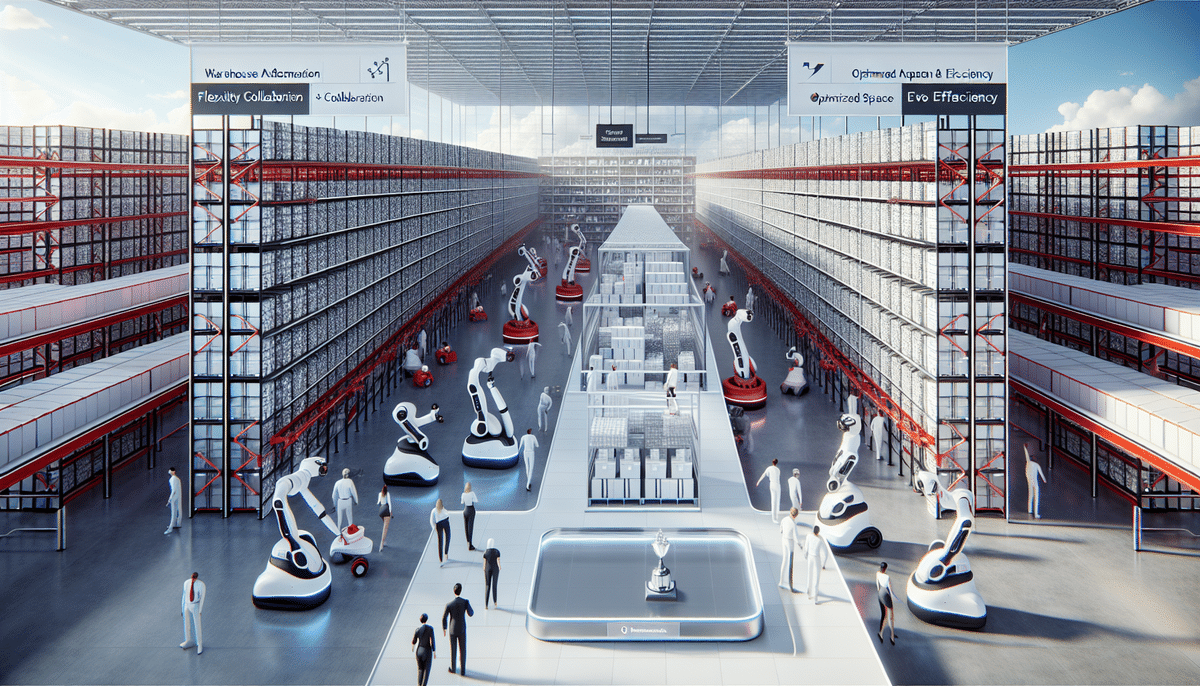

Warehouse automation is revolutionizing the logistics industry, enabling businesses to enhance efficiency, reduce labor costs, and meet the growing demands of e-commerce. Among the leading solutions in this space are Locus Robotics and AutoStore. This article provides a comprehensive comparison of these two technologies, exploring their functionalities, advantages, and suitability for different business needs.

Evolution of Warehouse Automation

The journey of warehouse automation has seen significant advancements over the past decade. Traditionally, warehouses relied heavily on manual labor and basic machinery like forklifts. However, the surge in e-commerce and the need for faster delivery times have accelerated the adoption of automated solutions.

According to a McKinsey report, the global warehouse automation market is projected to grow at a CAGR of 12.4% from 2021 to 2028, driven by innovations in robotics, artificial intelligence, and IoT integration.

Automated systems like Locus Robotics and AutoStore exemplify the technological strides made in this sector, offering scalable and efficient solutions tailored to modern warehouse operations.

Understanding Locus Robotics and AutoStore

Locus Robotics: Enhancing Order Fulfillment

Locus Robotics employs a fleet of autonomous mobile robots, known as LocusBots, designed to assist warehouse associates in picking and transporting orders. These robots seamlessly integrate with existing warehouse management systems to optimize inventory tracking and workflow efficiency.

Key features of Locus Robotics include:

- Flexibility: Easily adaptable to various product types and warehouse layouts.

- Advanced Sensors: Equipped with sensors and safety features to navigate safely alongside human workers.

- Scalability: Ability to scale operations up or down based on demand without extensive reconfiguration.

AutoStore: Maximizing Storage Density

AutoStore offers an automated storage and retrieval system (AS/RS) characterized by its cube storage design. This system utilizes a grid of stacked bins where products are stored, with robots moving above the grid to retrieve and store items as needed.

Key advantages of AutoStore include:

- High-Density Storage: Maximizes storage capacity within a compact footprint.

- Goods-to-Person Model: Robots deliver products directly to associates, minimizing the need for manual movement.

- Energy Efficiency: Optimized for continuous operation with low energy consumption.

Comparative Analysis: Locus Robotics vs. AutoStore

Technological Foundations

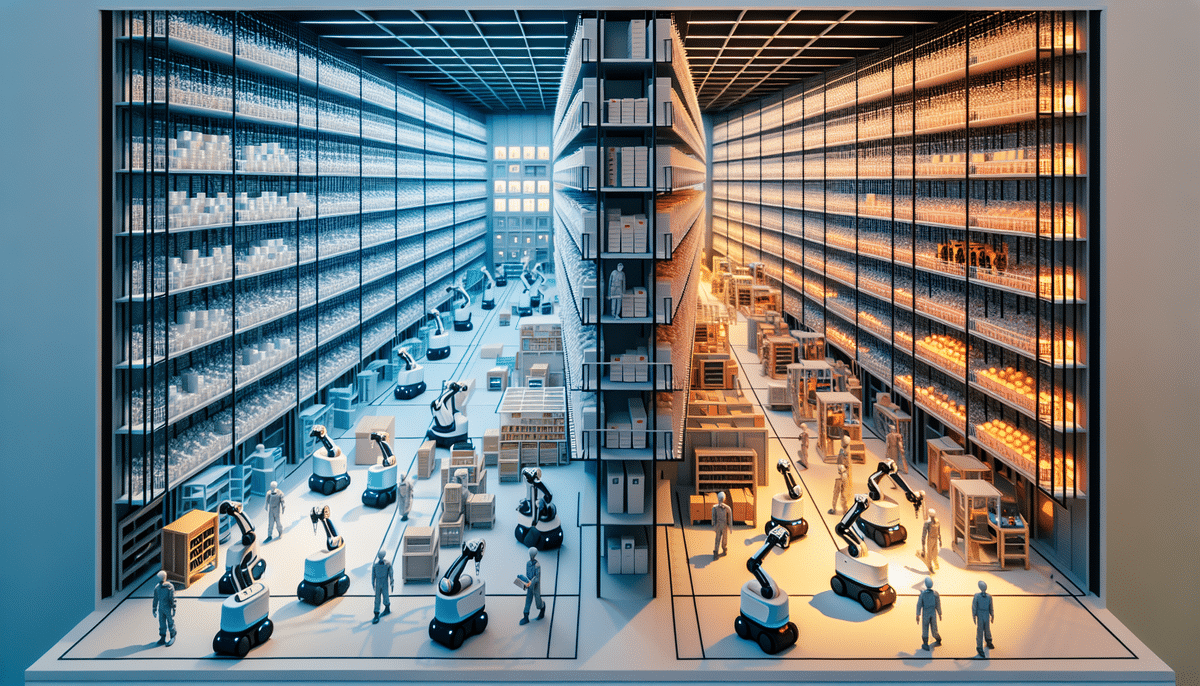

Locus Robotics relies on autonomous mobile robots that interact dynamically with their environment, leveraging AI and machine learning to optimize paths and tasks. In contrast, AutoStore’s system is built around a static grid of storage bins and robots that follow predefined routes to access products.

According to a study by Forrester, mobile robotics like those used by Locus Robotics offer greater adaptability and faster deployment in existing warehouse setups compared to more rigid systems like AutoStore.

Efficiency and Performance

In terms of speed, Locus Robotics excels in order fulfillment scenarios, swiftly navigating through warehouses to pick and deliver items. AutoStore, while slightly slower in movement, compensates with its ability to handle larger and heavier items, with robots capable of lifting up to 77 pounds compared to LocusBots' 50-pound capacity.

Moreover, AutoStore's high-density storage significantly reduces the warehouse footprint, allowing businesses to store more products in less space, which can be particularly advantageous for large-scale operations.

Cost-Effectiveness

The cost-effectiveness of each solution depends on the specific needs of the warehouse. Locus Robotics tends to be more economical for warehouses with high order volumes due to its efficient order fulfillment capabilities. On the other hand, AutoStore offers better value for larger warehouses requiring extensive storage solutions.

A cost-benefit analysis highlights that while the initial investment for AutoStore can be higher, the long-term savings from space utilization and operational efficiency can justify the expense for larger enterprises.

Suitability for Different Warehouse Sizes

Small to Medium-Sized Warehouses

For smaller warehouses with limited space and moderate order volumes, Locus Robotics offers a flexible and scalable solution. The mobility of LocusBots allows them to adapt to varying layouts and product assortments without significant infrastructure changes.

Large-Scale Warehouses

Large warehouses benefit more from AutoStore’s high-density storage capabilities. The cube storage system enables these facilities to manage vast inventories within a compact area, enhancing overall storage efficiency and order processing speeds.

User Experience and Maintenance

Operator Perspectives

Operators using Locus Robotics report improved job satisfaction due to reduced physical strain and increased efficiency in order fulfillment. The intuitive interface and real-time data analytics provide valuable insights for optimizing workflows.

Conversely, AutoStore users appreciate the streamlined operations and minimized manual handling, allowing them to focus on higher-value tasks. The goods-to-person model enhances productivity by reducing the time spent navigating the warehouse.

Maintenance and Support

Locus Robotics' system is designed for ease of maintenance, with fewer mechanical components that require regular upkeep. Their support team offers proactive monitoring and quick response times to address any issues.

AutoStore, while robust, involves more complex maintenance due to its intricate grid and robot system. Regular maintenance is essential to ensure smooth operation and prevent downtime, which can be more resource-intensive compared to Locus Robotics.

Real-World Implementations

Several prominent companies have successfully integrated Locus Robotics and AutoStore into their operations:

- Locus Robotics: American Eagle Outfitters, Boots, and Quiet Logistics leverage LocusBots to enhance their order fulfillment processes.

- AutoStore: Puma, Uniqlo, and Electrical Discount utilize AutoStore's high-density storage systems to manage large inventories efficiently.

Future Prospects of Warehouse Automation

The future of warehouse automation is poised for continued growth and innovation. Both Locus Robotics and AutoStore are investing in advanced technologies to stay ahead in the market:

- Locus Robotics: Focusing on machine learning and AI to handle more complex tasks and improve robot autonomy.

- AutoStore: Expanding its capabilities beyond storage and retrieval to include sorting and packing functionalities.

Emerging trends such as increased integration with IoT devices, enhanced data analytics, and collaborative human-robot interactions are expected to further transform warehouse operations, making them smarter and more efficient.

Conclusion: Choosing the Right Automation Solution for Your Business

Both Locus Robotics and AutoStore offer robust solutions for warehouse automation, each with its unique strengths. The optimal choice depends on various factors, including warehouse size, order volume, space constraints, and specific operational needs.

Businesses should conduct a thorough analysis of their workflows, budget, and long-term goals to determine which system aligns best with their objectives. Investing in the right automation technology can lead to significant improvements in efficiency, accuracy, and overall profitability.

For more insights into warehouse automation solutions, refer to industry reports from sources like McKinsey & Company and Forrester Research.