Understanding Warehouse Automation Solutions

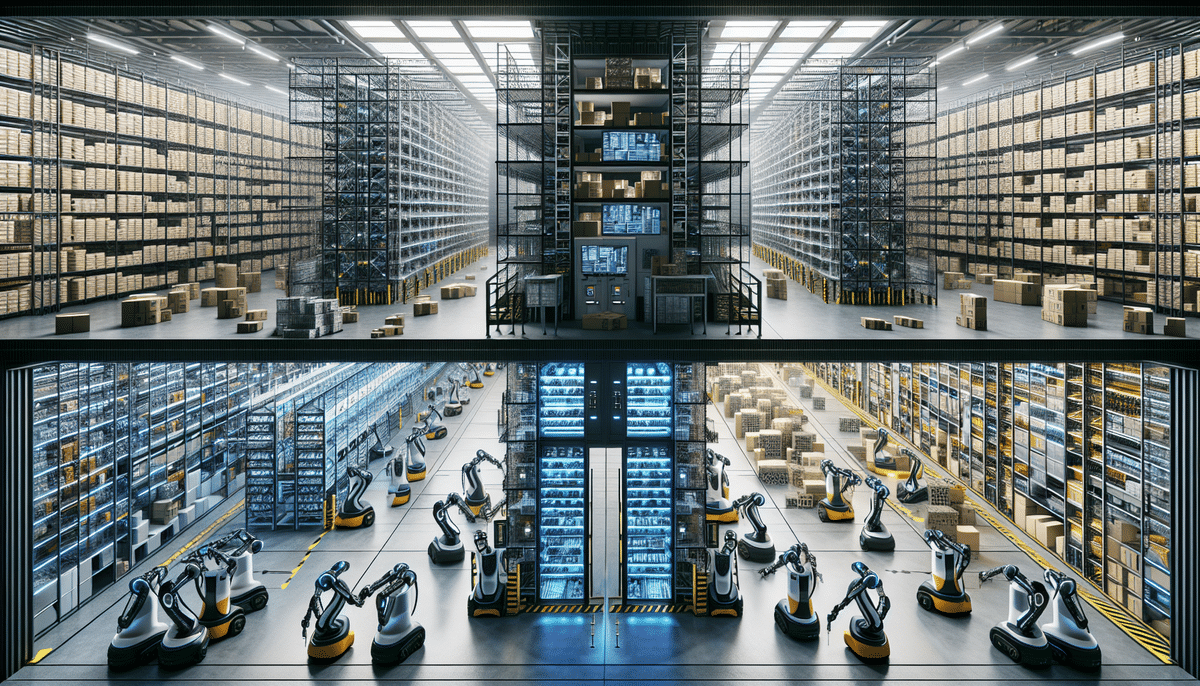

Warehouse automation has become a critical component for businesses aiming to enhance efficiency and productivity. Among the myriad of solutions available, Geek+ and AutoStore stand out as two of the most prominent options. Both technologies offer robust automation capabilities, but they differ significantly in their approaches and functionalities. This article delves into the key differences between Geek+ and AutoStore, providing insights to help you determine which solution best fits your business needs.

Geek+ vs. AutoStore: Key Differences

Technology and Functionality

Geek+ utilizes Autonomous Mobile Robots (AMRs) to navigate the warehouse, transporting goods efficiently across various locations. In contrast, AutoStore employs a fixed grid of bins accessed by specialized robots that move along rails, retrieving and storing items as needed. This fundamental difference in technology impacts how each system operates and integrates within a warehouse environment.

Flexibility and Scalability

Geek+ offers greater flexibility, making it adaptable to a wide range of warehouse layouts and configurations. This adaptability is particularly beneficial for businesses with unique or unconventional warehouse setups. On the other hand, AutoStore is optimized for more standardized warehouse layouts, providing high-density storage solutions that maximize space utilization.

Payload and Storage Capacity

Geek+ boasts a higher maximum payload capacity compared to AutoStore, allowing it to handle larger and heavier items. This feature makes Geek+ ideal for industries dealing with bulkier products. Conversely, AutoStore excels in storage density, enabling businesses to store more items within a confined space, which is advantageous for operations with limited warehouse space.

Choosing the Right Solution for Your Business

Assessing Warehouse Size and Layout

When selecting between Geek+ and AutoStore, consider the size and layout of your warehouse. Geek+ is well-suited for large warehouses with numerous aisles and diverse configurations, offering the flexibility to adapt to changing inventory needs. In contrast, AutoStore is ideal for smaller warehouses that benefit from high-density storage and streamlined operations.

Customization and Integration

Geek+ provides a high level of customization, allowing businesses to tailor the system to their specific requirements. This flexibility extends to integration with various Warehouse Management Systems (WMS), enhancing overall operational efficiency. AutoStore, while less customizable, offers a more standardized setup that can be easier to implement and maintain, especially for businesses seeking a plug-and-play solution.

Cost Considerations

Cost is a pivotal factor in deciding between Geek+ and AutoStore. Geek+ typically involves higher upfront costs due to its advanced AMR technology and customization capabilities. However, it may offer long-term cost savings through increased efficiency and scalability. AutoStore tends to have a lower initial investment but might incur higher maintenance and operational costs over time. It's essential to weigh these factors against your budget and long-term business goals.

Pros and Cons of Geek+ and AutoStore

Geek+

- Pros:

- Highly flexible and adaptable to various warehouse configurations

- Capable of handling heavier and bulkier loads

- Integrates seamlessly with multiple Warehouse Management Systems (WMS)

- Utilizes advanced AI and machine learning for optimized operations

- Cons:

- Higher initial investment compared to AutoStore

- Requires more frequent maintenance and specialized technicians

- Occupies more floor space due to the number of AMRs needed

AutoStore

- Pros:

- Lower upfront costs and easier implementation

- Superior vertical space utilization, allowing for higher storage density

- Less maintenance required compared to Geek+

- Compact footprint, ideal for warehouses with limited space

- Cons:

- Less flexibility in accommodating varied warehouse layouts

- Limited payload capacity, suitable for lighter items

- Less customizable, potentially limiting specific business needs

Implementation and Costs

Initial Investment

The initial cost of implementing Geek+ is generally higher due to the advanced AMR technology and the need for a more extensive setup. Businesses must consider whether the long-term benefits, such as increased scalability and efficiency, justify the upfront expenditure.

Maintenance and Support

Geek+ systems typically require more maintenance and specialized support, leading to higher ongoing costs. AutoStore, with its more standardized technology, tends to have lower maintenance requirements, making it a more cost-effective option for some businesses.

Real-Life Success Stories

Numerous businesses have successfully integrated Geek+ and AutoStore into their warehouse operations. For instance, Alibaba Group utilizes Geek+ solutions to automate its extensive warehouses, enhancing efficiency and order fulfillment speed. On the other hand, companies like Puma and Lufthansa Technik have implemented AutoStore systems to maximize their storage density and streamline their operations.

Conclusion

Both Geek+ and AutoStore offer cutting-edge warehouse automation solutions, each with its unique strengths and limitations. The optimal choice between the two hinges on your specific business requirements, including warehouse size, layout flexibility, inventory type, and budget constraints. By thoroughly assessing these factors and understanding the distinct features of each system, you can select the warehouse automation technology that best aligns with your operational goals and drives your business forward.