FedEx Provides Comprehensive Guidelines for Shipping Oxidizing Materials

Shipping oxidizing materials is a hazardous task that necessitates strict adherence to safety guidelines and regulations. Understanding what oxidizing materials are and recognizing the associated risks is crucial for businesses and individuals involved in transporting these hazardous items. FedEx, a leading transportation company, offers detailed guidelines to ensure the safe and efficient handling and shipping of oxidizing materials. This article delves into the dangers of oxidizing materials and outlines best practices for packaging, labeling, and transporting them.

What Are Oxidizing Materials and Why Are They Hazardous?

Oxidizing materials are substances that release oxygen or other oxidizing agents during chemical reactions. Commonly utilized in industrial processes, scientific experiments, and household products, examples of oxidizing materials include hydrogen peroxide, nitric acid, and potassium permanganate. These materials are hazardous because they can cause combustible substances to ignite or explode if mishandled.

Beyond the risk of fires and explosions, oxidizing materials pose significant health hazards. Exposure can lead to skin and eye irritation, respiratory issues, and in severe cases, chemical burns. Proper handling, including the use of appropriate protective equipment and adherence to storage and disposal protocols, is essential to mitigate these risks.

Understanding the Dangers of Shipping Oxidizing Materials by Air

Transporting oxidizing materials by air introduces additional risks due to fluctuating pressure and temperature conditions during flights. Reduced air pressure in cargo holds may cause containers to leak or rupture, while low temperatures at high altitudes can destabilize certain materials. Moreover, the limited space on airplanes restricts the types and quantities of hazardous materials that can be safely shipped.

Not all oxidizing materials behave similarly under these conditions. For instance, hydrogen peroxide is more prone to decomposition when exposed to pressure and temperature changes, potentially releasing oxygen gas and heightening the risk of fire or explosion. In contrast, potassium permanganate may be less sensitive but still poses risks if it contacts incompatible materials during transport.

To minimize these dangers, it is imperative to accurately classify and package oxidizing materials in compliance with international regulations. This involves using suitable packaging materials, such as UN-approved drums or containers, and clearly labeling packages with the necessary hazard warnings. Additionally, ensuring that all personnel involved in the transport process are adequately trained and equipped to handle emergencies is crucial.

Identifying and Classifying Oxidizing Materials for Safe Shipping

The initial step in the safe shipping of hazardous materials is proper identification and classification. According to the United Nations Committee of Experts on the Transport of Dangerous Goods (UNCEGTD), oxidizing materials fall under hazard class 5.1. FedEx recommends consulting the United Nations Manual of Tests and Criteria for comprehensive guidance on testing and classifying these substances.

Proper classification involves understanding the specific properties and reactions of each oxidizing material. For example, hydrogen peroxide is a strong oxidizer used in bleaching and disinfecting, while sodium chlorate serves in various industrial applications. Accurate identification ensures that the materials are handled and shipped in a manner that mitigates potential hazards.

Importance of Proper Packaging and Labeling for Oxidizing Materials

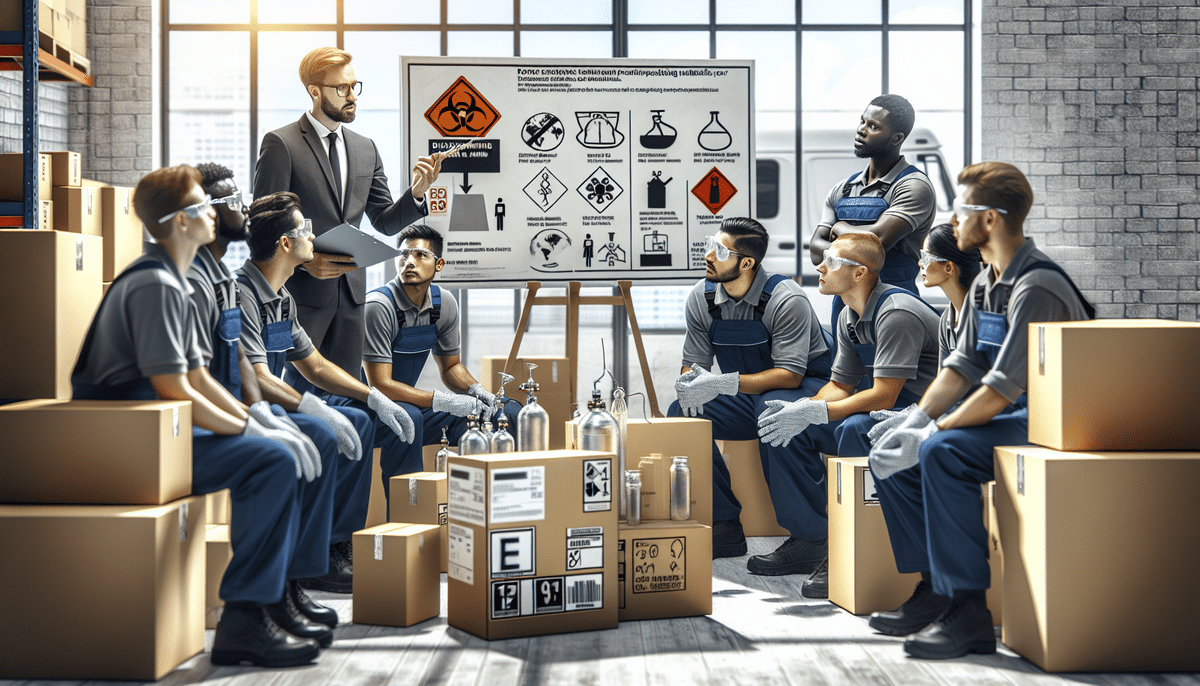

Effective packaging and labeling are critical components of the safe shipping process for oxidizing materials. FedEx mandates the use of DOT-approved packaging tailored to the specific type and quantity of hazardous material being transported. Each package must feature the appropriate hazard class label, along with the shipping name and identification number.

In addition to packaging, ensuring that personnel handling oxidizing materials are well-trained and equipped with necessary personal protective equipment (PPE) is essential. This includes items such as gloves, goggles, and respirators, tailored to the specific material being handled.

Proper storage is equally important. Oxidizing materials should be stored in cool, dry, and well-ventilated areas, away from heat sources and potential ignition points. This practice helps prevent unwanted chemical reactions that could lead to fires or explosions.

Best Practices for Handling and Transporting Oxidizing Materials

Adhering to best practices is vital for the safe handling and transportation of oxidizing materials. These practices include:

- Utilizing appropriate personal protective equipment (PPE)

- Handling materials in well-ventilated areas

- Minimizing risks associated with shock, friction, heat, and sparks

- Providing comprehensive training to employees about the hazards of oxidizing materials

Furthermore, proper labeling and packaging are crucial. Packaging should be designed to prevent leaks or spills, and all packages must be clearly marked with the relevant hazard warning labels. Compliance with local, state, and federal regulations is mandatory to ensure safe transportation.

Compliance with Federal Regulations to Prevent Accidents and Fines

Compliance with federal regulations is imperative to prevent accidents and avoid significant fines. The Pipeline and Hazardous Materials Safety Administration (PHMSA) under the Department of Transportation sets stringent regulations for shipping hazardous materials. Non-compliance can result in hefty fines and penalties for both shippers and carriers.

FedEx ensures full compliance with all applicable federal regulations related to the handling and shipping of oxidizing materials. This commitment is reflected in their rigorous safety protocols, which include regular employee training, strict adherence to packaging and labeling standards, and thorough inspections of all shipments prior to dispatch.

Additionally, FedEx boasts a dedicated team of hazardous materials experts who assist customers in navigating complex shipping requirements. These professionals provide guidance on proper packaging, labeling, and documentation to ensure full regulatory compliance.

Managing Risk: Tips for Businesses Shipping Oxidizing Materials with FedEx

Businesses that frequently ship oxidizing materials can enhance safety and efficiency by developing a comprehensive risk management plan. Key components of such a plan include:

- Conducting regular hazard assessments

- Implementing robust safety practices

- Reviewing and optimizing shipping procedures to identify and mitigate potential hazards

FedEx supports businesses in formulating and executing effective risk management strategies. Proper labeling and packaging, using appropriate containers and providing detailed hazard warnings, are fundamental to ensuring safe transportation.

Employee training is another critical aspect. By educating staff on the correct handling and transportation procedures for oxidizing materials, businesses can significantly reduce the risk of accidents or incidents during shipping.

FedEx’s Commitment to Safe Shipping Practices for Hazardous Materials

FedEx is deeply committed to safety excellence, evidenced by its comprehensive hazardous materials program that aligns with all federal regulations. This program encompasses employee training and education, well-defined procedures for handling and transporting hazardous materials, and an ongoing dedication to continuous improvement.

Advanced technology plays a pivotal role in FedEx’s safety initiatives. The company employs specialized packaging and labeling solutions, alongside real-time tracking and monitoring systems, to ensure the secure transportation of hazardous materials. FedEx also collaborates closely with regulatory agencies and industry organizations to stay abreast of the latest safety standards and best practices.

Conclusion: The Benefits of Safe Shipping Practices for All Involved Parties

Implementing safe shipping practices for oxidizing materials is essential for safeguarding individual and public safety, reducing the risk of accidents, and avoiding costly fines and penalties. By adhering to the guidelines provided by FedEx, businesses and individuals can ensure that hazardous materials are handled and shipped safely and efficiently. Proper safety practices not only protect all stakeholders but also contribute to maintaining a safe and healthy environment.

Beyond safety, adopting these practices offers financial advantages. Preventing accidents and avoiding fines helps businesses save money and protect their reputations. Additionally, proper handling and shipping reduce the likelihood of material damage, minimizing the need for expensive replacements or repairs.

Environmental protection is another significant benefit. By minimizing the risk of spills and leaks, businesses and individuals help prevent the contamination of soil and water sources, thereby supporting the health and well-being of local communities and preserving the environment.