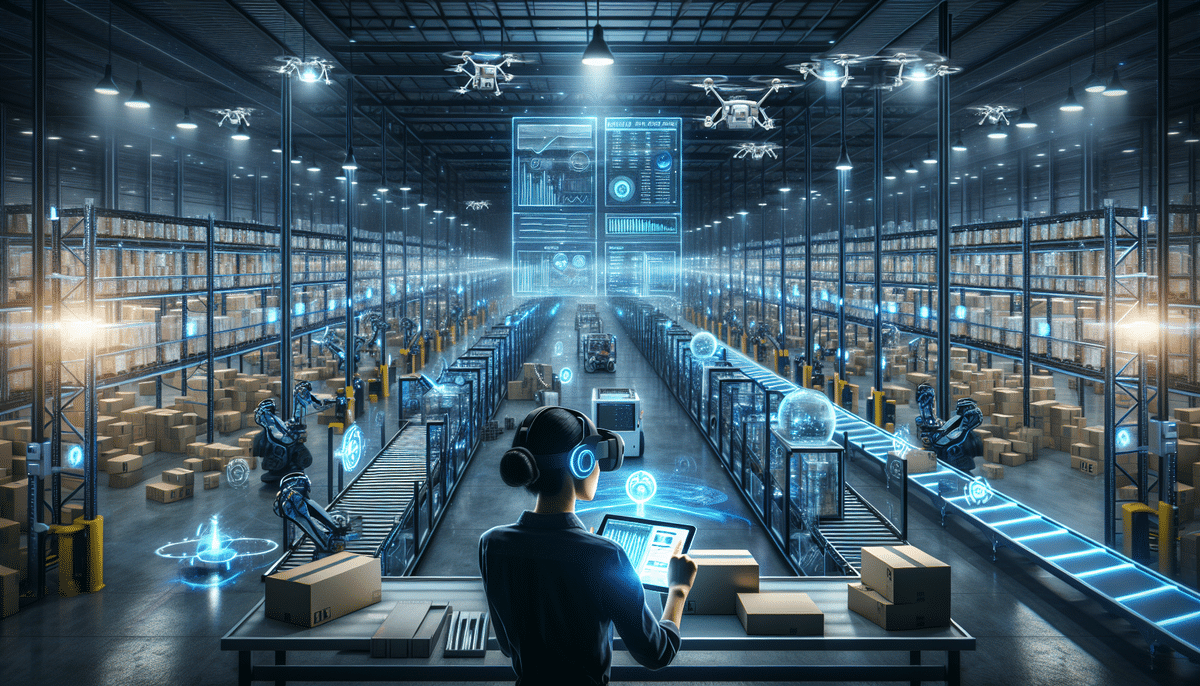

Introduction to Smart Technology in Warehousing

Warehouses have experienced a significant transformation over the past few years, driven primarily by the integration of smart technology. This technological evolution has not only enhanced operational efficiency and productivity but has also revolutionized inventory control and management. In this article, we explore the rise of smart technology in warehouses, outlining its advantages, the future outlook of warehouse management, and strategies for successful implementation.

Key Smart Technologies Revolutionizing Warehousing

Internet of Things (IoT)

The Internet of Things (IoT) plays a pivotal role in modern warehousing by connecting devices and sensors to monitor and manage various aspects of operations. IoT-enabled devices collect real-time data on inventory levels, equipment performance, and environmental conditions, providing valuable insights for efficient decision-making. Learn more about IoT in warehousing from IBM's IoT solutions.

Artificial Intelligence (AI)

Artificial Intelligence (AI) enhances warehousing operations by enabling predictive analytics, demand forecasting, and autonomous decision-making. AI-driven systems analyze vast amounts of data to optimize inventory levels, streamline order fulfillment, and improve overall operational efficiency. According to a report by McKinsey & Company, AI can reduce operational costs by up to 20% in warehousing environments.

Robotics and Automation

Robots and automated systems are increasingly being deployed in warehouses to handle tasks such as picking, packing, sorting, and transporting goods. These technologies enhance speed and accuracy, reduce human error, and allow for 24/7 operations without the need for breaks. A study by McKinsey & Company suggests that automation can boost warehouse productivity by up to 30%.

Augmented Reality (AR)

Augmented Reality (AR) is being used to assist warehouse workers by overlaying digital information onto their physical environment. AR devices can provide real-time instructions, highlight picking locations, and guide workers through complex warehouse layouts, thereby increasing efficiency and reducing errors. Companies like Microsoft HoloLens offer AR solutions tailored for warehouse operations.

Benefits of Smart Technology in Warehousing

Enhanced Efficiency and Productivity

Smart technology significantly enhances the efficiency and productivity of warehouse operations. Automation and robotic systems increase the speed and accuracy of tasks such as order fulfillment and inventory management. Warehouse Management Systems (WMS) integrated with smart technologies provide real-time tracking and monitoring, enabling faster decision-making and reducing lead times. This results in higher throughput and improved customer satisfaction.

Improved Inventory Control

Advanced inventory management systems powered by smart technology offer precise tracking and control over stock levels. Technologies like RFID and barcode scanning enable real-time visibility into inventory, reducing the likelihood of stockouts and overstocking. Enhanced inventory control leads to better demand forecasting, efficient stock rotation, and minimized waste, directly contributing to increased profitability. According to Statista, effective inventory management can reduce holding costs by 25%.

Sustainability and Energy Efficiency

Smart technologies contribute to environmental sustainability by optimizing energy usage and reducing waste. Automated lighting and climate control systems adjust based on real-time data, minimizing energy consumption. Additionally, precise inventory management prevents overstocking and reduces product spoilage, decreasing waste. The Environmental Protection Agency (EPA) highlights that energy-efficient warehouse technologies can lower energy costs by up to 30%.

Data-Driven Decision Making

Advanced Analytics and Machine Learning

Data collected from various smart devices and sensors is analyzed using advanced analytics and machine learning algorithms to uncover patterns and insights. These analytics enable warehouses to optimize operations, predict demand trends, and make informed decisions about inventory replenishment and workforce management. Machine learning models can forecast future demands with high accuracy, allowing for proactive adjustments in operations.

Real-Time Monitoring and Reporting

Real-time monitoring systems provide continuous oversight of warehouse operations, allowing managers to identify and address issues promptly. Dashboards and real-time reports offer visibility into key performance indicators (KPIs) such as order processing times, inventory turnover rates, and energy usage. This immediate access to data facilitates timely interventions and strategic planning to enhance operational efficiency.

Challenges and Solutions in Smart Warehouse Integration

High Initial Investment

Implementing smart technologies in warehouses often requires significant upfront investment in hardware, software, and infrastructure. To mitigate these costs, businesses can adopt phased implementation strategies, prioritize essential technologies, and seek financing options. Additionally, demonstrating the long-term return on investment (ROI) through operational savings and increased revenue can justify the initial expenditure.

Expertise and Training

The integration of smart technologies necessitates specialized skills and knowledge. A lack of expertise can hinder the effective deployment and utilization of these systems. To address this, companies should invest in employee training and development programs, partner with technology providers offering support and training, and consider hiring skilled professionals to oversee technology integration.

Security and Privacy Concerns

The increased connectivity of devices in smart warehouses raises security and privacy concerns. Protecting sensitive data from cyber threats is paramount. Implementing robust cybersecurity measures, such as encryption, access controls, and regular security audits, can safeguard against potential breaches. Additionally, ensuring compliance with data protection regulations helps maintain trust and protect customer information.

Future Trends in Smart Warehouse Technology

Autonomous Vehicles and Drones

The use of autonomous vehicles and drones in warehouses is expected to grow, further automating the movement of goods and inventory management. These technologies can navigate through warehouse floors, transport items between storage areas, and conduct inventory checks with minimal human intervention.

Blockchain for Supply Chain Transparency

Blockchain technology offers a secure and transparent way to track goods throughout the supply chain. By providing an immutable ledger of transactions, blockchain enhances traceability, reduces fraud, and ensures the integrity of data related to the movement and storage of goods.

Integration with E-commerce Platforms

As e-commerce continues to expand, integrating warehouse management systems with online platforms becomes increasingly important. Seamless integration ensures efficient order processing, real-time inventory updates, and enhanced customer satisfaction by providing accurate delivery timelines and availability information.

Implementing a Successful Smart Technology Strategy for Your Warehouse

To successfully implement smart technology in warehouses, businesses should follow a strategic approach:

- Define Goals and Objectives: Clearly outline what you aim to achieve with smart technologies, such as increased efficiency, better inventory control, or enhanced customer satisfaction.

- Assess Current Operations: Evaluate existing processes to identify areas where smart technology can provide the most significant benefits.

- Select Appropriate Technologies: Choose technologies that align with your goals and can be integrated seamlessly with your current systems.

- Plan for Scalability: Ensure that the chosen solutions are scalable and can adapt to future growth and changing business needs.

- Invest in Training: Provide comprehensive training to employees to ensure they can effectively use and manage the new technologies.

- Monitor and Evaluate: Continuously monitor the performance of implemented technologies and make necessary adjustments to optimize operations.

Conclusion

The integration of smart technology in warehouses has ushered in a new era of efficiency, productivity, and sustainability. Technologies such as IoT, AI, robotics, and augmented reality are transforming traditional warehousing operations, offering significant advantages in inventory control, operational efficiency, and environmental impact. By adopting a strategic approach to implementation and addressing potential challenges, businesses can harness the full potential of smart technologies to gain a competitive edge in the industry.