Introduction to Warehouse Automation: Dematic and Amazon Robotics

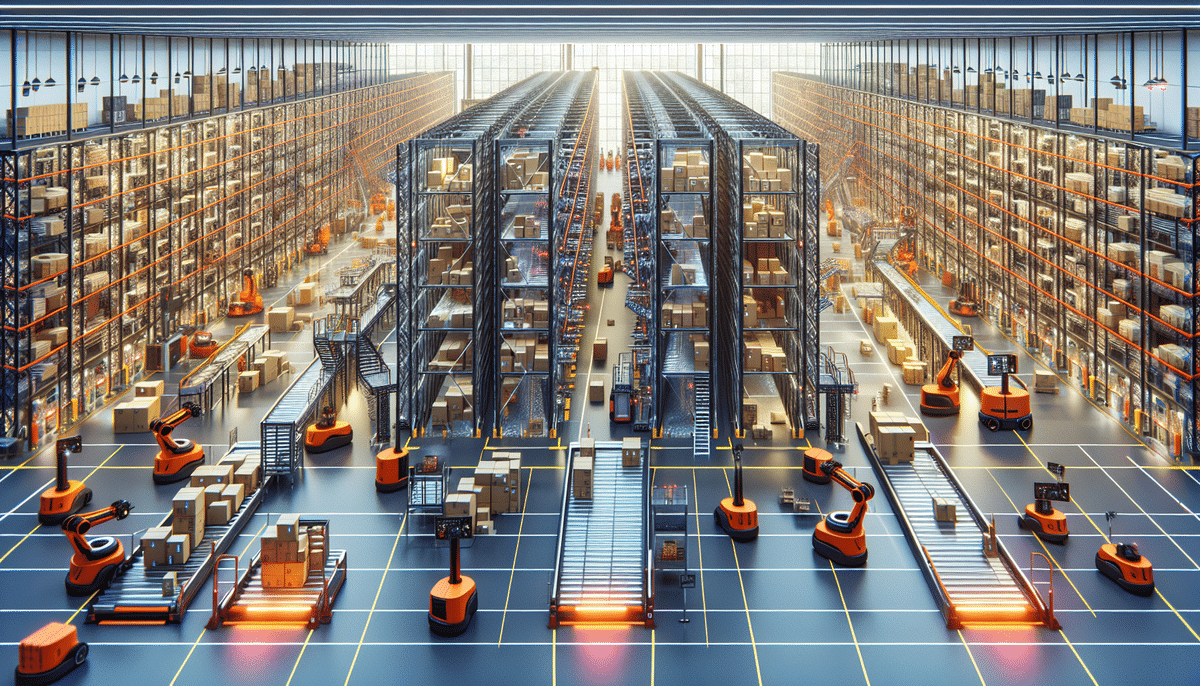

Dematic and Amazon Robotics (formerly Kiva Systems) are two leading robotic systems revolutionizing modern warehousing. Renowned for their efficiency, speed, and accuracy, these systems play a pivotal role in enhancing order fulfillment processes. This article provides an in-depth comparison of Dematic and Amazon Robotics, exploring their history, benefits, differences, and their overall impact on warehouse productivity and sustainability.

History and Evolution of Dematic and Amazon Robotics

Dematic: A Legacy of Innovation

Founded in 1819 in Germany, Dematic has evolved into a global supplier of advanced intralogistics solutions. Through various mergers and acquisitions, Dematic now operates in over 100 countries, offering products like automated storage and retrieval systems (ASRS), warehouse management systems (WMS), conveyor systems, and robotics.

Amazon Robotics: From Kiva Systems to Industry Leader

Kiva Systems, established in 2003 by Mick Mountz, was acquired by Amazon in 2012 and rebranded as Amazon Robotics. This acquisition transformed e-commerce fulfillment by introducing mobile robots that efficiently navigate warehouse floors to transport goods. Amazon Robotics has since expanded its product line and partnered with various companies to integrate its technology across the industry.

Comparative Analysis of Dematic and Amazon Robotics

Key Similarities

Both Dematic and Amazon Robotics focus on automating warehouse processes to increase speed and accuracy in order fulfillment. They utilize advanced robotics and software solutions to optimize workflows, reduce manual labor, and enhance inventory management.

Key Differences

The primary distinction lies in their approach to automation. Dematic emphasizes ASRS and comprehensive WMS, suited for handling larger loads and optimizing storage. In contrast, Amazon Robotics relies on mobile robots, offering greater flexibility and adaptability in navigating varying warehouse environments.

Pros and Cons

- Dematic: Capable of handling larger loads, highly customizable ASRS, advanced WMS integration.

- Amazon Robotics: Flexible and adaptable mobile robots, easier implementation, lower cost of ownership.

However, Amazon Robotics may have limitations in load capacity and longer lead times for certain deployments.

Impact on Warehouse Efficiency and Productivity

Implementing Dematic and Amazon Robotics systems has demonstrated significant improvements in warehouse operations. For instance, Zara's adoption of Dematic's ASRS in its Spanish distribution center resulted in a 50% increase in efficiency. Additionally, Amazon reports that integrating Amazon Robotics across its fulfillment centers has led to a 20% reduction in operating costs. These enhancements translate to faster order fulfillment, reduced errors, and optimized resource utilization.

Implementing Automated Systems in Warehousing

Factors to Consider

- Nature of products and order volume.

- Warehouse size and layout.

- Budgetary constraints and ROI.

- Technical expertise and maintenance capabilities.

Cost Analysis

The initial investment for Dematic or Amazon Robotics systems varies based on system complexity and warehouse size. Dematic's solutions may require higher upfront costs due to extensive infrastructure, while Amazon Robotics offers scalable options with lower initial expenditures. Long-term savings stem from reduced labor costs and enhanced operational efficiency.

Future Developments in Robotic Automation

The future of warehouse automation is poised for advancements such as augmented reality integrations, enhanced machine learning algorithms, and more sophisticated sensor technologies. These innovations will further increase the efficiency and adaptability of robotic systems, enabling even greater automation and smarter warehouse operations.

Addressing Common Misconceptions

Human Workforce and Automation

Contrary to popular belief, robotic automation complements rather than replaces human workers. Automated systems handle repetitive and hazardous tasks, allowing employees to focus on complex, value-added activities such as quality control and customer service. This synergy enhances overall productivity and workplace safety.

Conclusion

Dematic and Amazon Robotics offer robust solutions for enhancing warehouse efficiency and order fulfillment. By understanding their unique strengths and aligning them with specific operational needs, businesses can leverage these systems to achieve significant improvements in productivity, accuracy, and sustainability. Strategic implementation of automated systems is essential for maintaining a competitive advantage in the rapidly evolving logistics and warehousing landscape.