Transforming Warehousing: The Impact of Robotic Automation

Robotic automation has been revolutionizing the warehousing industry, enhancing efficiency, speed, and safety. With the rise of innovative technologies, warehouses are becoming more streamlined and productive. This article explores the advancements in warehouse robotics, focusing on two industry leaders, Geek+ and Locus Robotics, to help you make informed decisions for your warehouse automation needs.

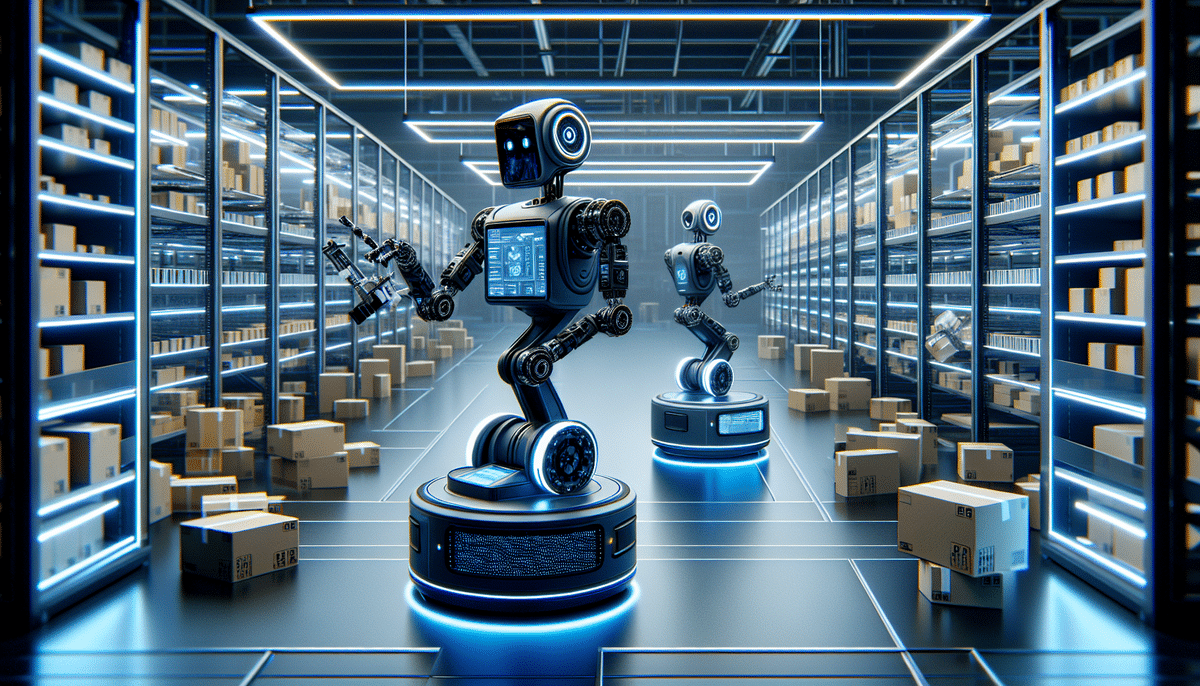

The Rise of Robotics in Warehousing

The demand for advanced automation in warehousing has surged due to several factors. The exponential growth of e-commerce and online shopping has consistently elevated warehousing demands. Additionally, the labor-intensive nature of warehousing tasks often results in human fatigue, errors, and workplace injuries. Businesses are increasingly seeking cost-effective and eco-friendly solutions to boost productivity and streamline operations.

Advantages of Robotic Automation

- 24/7 Operations: Unlike human workers, robots can operate continuously without breaks, significantly increasing the speed and efficiency of warehouse operations.

- Handling Heavy Loads: Robots can effortlessly lift and move heavy items, reducing the risk of injury and enhancing productivity in industries like construction and manufacturing.

- Safety in Hazardous Environments: Robots can be programmed to work in environments with high temperatures or toxic chemicals, safeguarding human workers from potential harm.

According to a McKinsey report, the implementation of robotics can increase overall warehouse productivity by up to 30%.

Leading the Charge: Geek+ vs. Locus Robotics

Geek+ and Locus Robotics stand out as prominent providers of robotic solutions in the warehousing sector. Both companies offer innovative technologies that are reshaping the industry, but they focus on different aspects of warehouse automation.

Geek+: Comprehensive Automation Solutions

With over a decade of experience, Geek+ specializes in autonomous shelf and bin management, automated forklifts, conveyors, and guided vehicles. Their proprietary algorithms and AI optimize warehouse layouts, streamlining workflows and minimizing repetitive tasks.

- Customization: Geek+'s flexible technology allows for extensive customization to meet complex warehouse needs.

- Sustainability: Their solutions are designed to reduce energy consumption and waste, supporting companies' environmental goals.

- Safety Features: Equipped with sensors and safety mechanisms, Geek+ robots ensure a secure working environment.

Geek+ has been recognized in various industry awards for its commitment to innovation and sustainability.

Locus Robotics: Enhancing Picking and Transportation

Locus Robotics focuses on mobile robots that excel in picking and transporting tasks within warehouses. Their solutions, including LocusBot, LocusFetch, and LocusPilot, integrate real-time tracking, inventory management, and data analytics to enhance operational efficiency.

- Scalability: Locus Robotics' solutions are easily scalable, making them suitable for businesses of all sizes.

- Integration: Their systems seamlessly integrate with existing warehouse infrastructure, ensuring minimal disruption during deployment.

- Productivity: By automating picking and transportation, Locus Robotics significantly reduces human error and increases order fulfillment speed.

According to a Robotics Business Review, companies implementing mobile robots can see a 50% increase in picking accuracy.

Comparing Geek+ and Locus Robotics

While both Geek+ and Locus Robotics offer cutting-edge solutions, they cater to different aspects of warehouse operations and have distinct advantages.

Features and Benefits

Geek+ provides a broader range of automation solutions, including inventory management and autonomous conveyors, making it ideal for businesses with diverse automation needs. In contrast, Locus Robotics specializes in mobile picking and transportation, suitable for companies aiming to enhance these specific processes.

Pricing Models

Both companies use a flexible Software-as-a-Service (SaaS) pricing model, allowing businesses to subscribe based on their requirements. However, Geek+ offers a pay-per-pick model, charging based on the number of items processed. Locus Robotics employs a pay-per-bot model, where businesses pay per robot deployed. The choice between these models depends on the specific operational demands and budget considerations of the business.

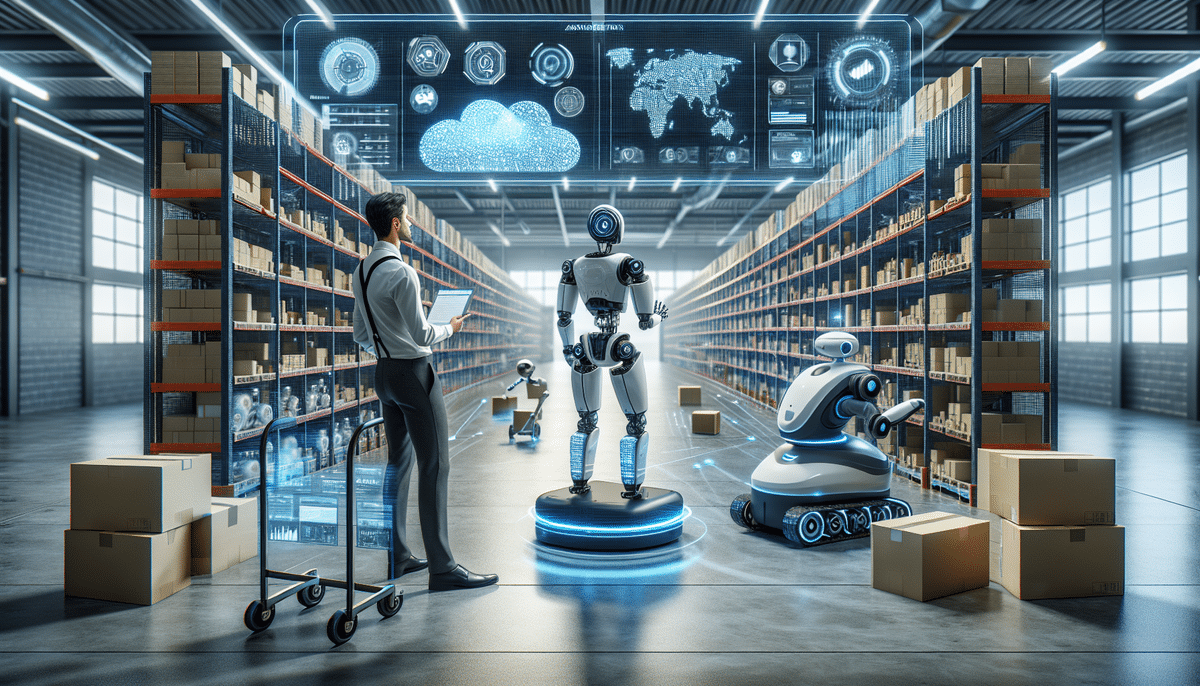

The Impact of Robotics on Warehouse Efficiency and Productivity

Robotic automation has a profound impact on warehouse efficiency and productivity. By delegating repetitive and labor-intensive tasks to robots, human workers can focus on higher-value activities, leading to a higher return on investment. Automation reduces error rates, ensures consistent quality, and enables warehouses to operate around the clock, enhancing order turnaround times and customer satisfaction.

- Increased Throughput: Robots can handle a higher volume of tasks at a consistent pace.

- Enhanced Accuracy: Automation minimizes human errors in order fulfillment.

- Operational Flexibility: Robots can adapt to various tasks and environments, providing versatile support across different warehouse operations.

Studies from the Forbes Technology Council highlight that warehouses implementing robotics see up to a 20% reduction in operational costs.

Choosing the Right Robotics Partner for Your Warehouse

Selecting the appropriate robotics provider is crucial for maximizing the benefits of automation. Consider the following factors to determine the best fit for your business:

- Operational Needs: Identify the specific tasks you wish to automate and choose a provider that offers specialized solutions for those functions.

- Integration Capability: Assess how seamlessly the provider's solutions can integrate with your existing warehouse layout and systems.

- Scalability: Ensure the provider can scale their solutions to match your business growth and evolving operational demands.

- Support and Maintenance: Opt for a provider that offers robust customer support and post-deployment services to ensure smooth operations.

- Cost-Effectiveness: Compare pricing models to determine which offers the best value based on your specific warehouse requirements.

Future Trends in Warehouse Robotics

The future of warehouse robotics is poised for significant advancements, with companies like Geek+ and Locus Robotics continuously innovating to meet the dynamic needs of the industry.

- Advanced AI and Machine Learning: Enhanced algorithms will enable robots to perform more complex tasks with greater autonomy.

- Drone Integration: Companies like Geek+ are exploring drone-based solutions for indoor operations, further expanding automation capabilities.

- Enhanced Analytics: Locus Robotics is focusing on integrating advanced data analytics to drive better performance and operational efficiency.

- Collaborative Robots: The development of robots that can work alongside human workers safely and efficiently will become more prevalent.

According to a Gartner report, the robotics market is expected to grow by 15% annually, reaching new heights in automation capabilities.

Common Misconceptions About Warehouse Robotics

Several misconceptions surround the adoption of robotics in warehouses:

- Job Losses: Contrary to popular belief, automation often creates more high-skill jobs and allows workers to engage in higher-value tasks.

- Suitability for Only Large-Scale Operations: Warehouse automation solutions are scalable and can benefit businesses of all sizes, including small and medium enterprises.

- High Implementation Costs: Flexible pricing models, such as SaaS, make robotic solutions accessible without exorbitant upfront investments.

Embracing automation can lead to safer workplaces, higher productivity, and more strategic use of human labor.

Case Studies: Successful Implementations of Robotics Solutions

Numerous companies have successfully integrated Geek+ and Locus Robotics solutions into their operations, yielding significant improvements:

- Alibaba: Leveraged Geek+ automation to enhance its vast e-commerce fulfillment centers, increasing order accuracy and reducing processing times.

- DHL: Implemented Locus Robotics' mobile solutions to streamline its global logistics operations, achieving higher efficiency and faster delivery times.

- Decathlon: Utilized Geek+ systems to manage inventory more effectively, resulting in improved stock management and reduced waste.

Expert Insights on the Future of Warehouse Automation

Industry leaders share their perspectives on the evolving landscape of warehouse automation:

- Scalability and Flexibility: Experts emphasize the importance of scalable and flexible solutions that can adapt to changing operational demands.

- Integration with Emerging Technologies: The integration of AI, machine learning, and IoT with robotics will drive further advancements in automation.

- Focus on Sustainability: Future automation solutions will increasingly prioritize energy efficiency and sustainable practices.

According to an interview with a Supply Chain Digital expert, the next decade will witness transformative changes in warehouse operations driven by continuous innovations in robotics and automation technologies.

Conclusion: Choosing the Right Automation Partner

Implementing the right robotic automation solutions is pivotal for enhancing warehouse efficiency and productivity. Geek+ and Locus Robotics offer innovative and tailored solutions that cater to diverse operational needs. By carefully evaluating your specific requirements, operational workflows, and budget considerations, you can select a partner that aligns with your business goals and drives sustained growth.