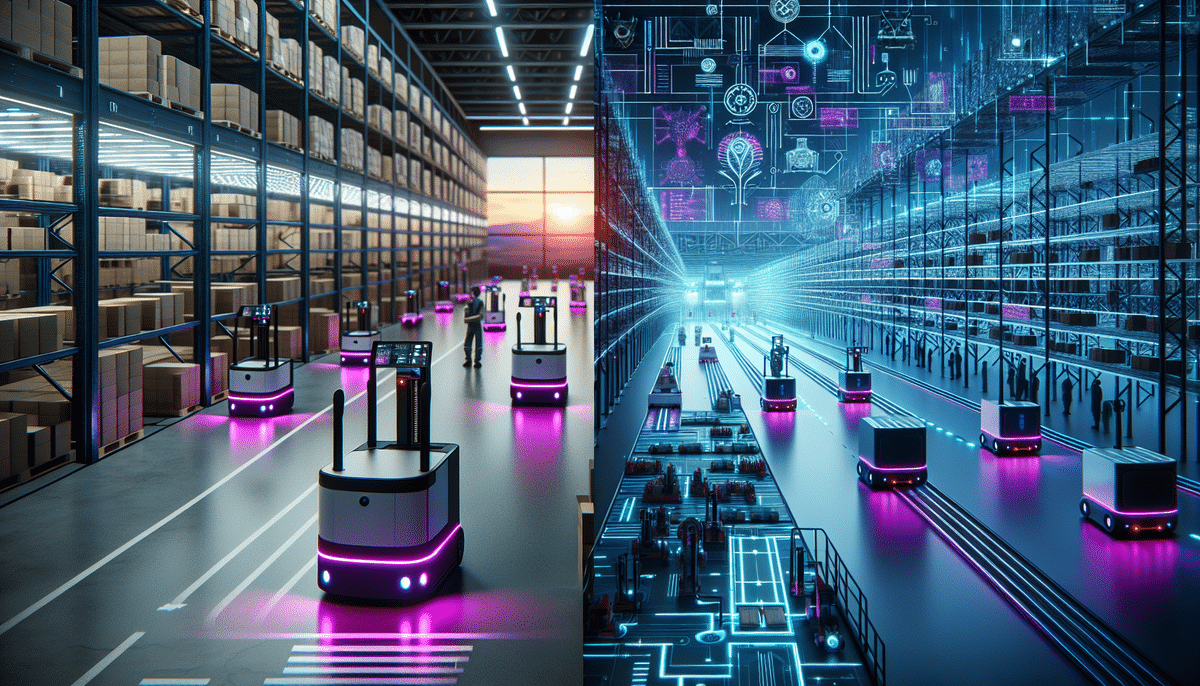

Introduction: The Critical Role of Robotics in Modern Warehousing

In today's rapidly evolving technological landscape, robots have become indispensable across various industries, with warehousing standing out as a prime beneficiary of automation advancements. Warehouse robotics are revolutionizing logistics by performing tasks such as storage, retrieval, packing, and transportation of goods with unparalleled efficiency. This article delves into two leading warehouse robotics solutions, Amazon Robotics (formerly Kiva Systems) and Knapp, comparing their features, advantages, and distinguishing factors to help businesses make informed decisions.

Implementing robotics in warehousing offers significant advantages, including enhanced efficiency and productivity. Robots can operate continuously without fatigue, enabling them to perform tasks more swiftly and accurately than human laborers. This not only saves time but also minimizes errors and workplace accidents, leading to a more streamlined and safer operational environment.

Moreover, robotics contribute to substantial cost savings. Although the initial investment in automation technology can be considerable, the long-term benefits of increased productivity and reduced labor costs often outweigh these expenses. By automating repetitive and strenuous tasks, robots allow human employees to focus on more complex and value-added activities, fostering a more skilled and motivated workforce.

Overview of Warehouse Robotics Solutions

Amazon Robotics: History, Features, and Advantages

History

Amazon Robotics, originally known as Kiva Systems, was founded in 2003 and acquired by Amazon in 2012. Since then, it has been pivotal in transforming Amazon's warehousing operations through automation.

Features

- Mobile units designed to transport entire shelves of inventory to human pickers.

- Seamless integration with warehouse management systems.

- Advanced navigation using sensors and cameras for efficient movement.

- Scalable deployment to match varying operational demands.

Advantages

Amazon Robotics significantly enhances order fulfillment speed and accuracy while reducing the physical strain on employees. The system's flexibility allows for rapid reconfiguration of warehouse layouts, adapting to changing inventory and market demands without substantial downtime or retraining costs.

Knapp: History, Features, and Advantages

History

Knapp has been a global leader in warehouse automation for over seven decades, continually innovating to provide robust and efficient robotic solutions tailored to diverse industrial needs.

Features

- Shuttle systems that use autonomous carts to transport goods within the warehouse.

- Integration with advanced warehouse management software for real-time tracking.

- Versatile configurations suitable for both horizontal and vertical transportation.

- High precision and accuracy in order picking and inventory management.

Advantages

Knapp's shuttle systems offer exceptional scalability and adaptability, making them ideal for large-scale warehouses with complex inventory requirements. The high accuracy provided by Knapp robots minimizes errors, which is crucial for industries demanding stringent quality control, such as pharmaceuticals and electronics.

Comparative Analysis of Amazon Robotics and Knapp

Efficiency and Productivity

Both Amazon Robotics and Knapp are engineered to boost warehouse efficiency and productivity, albeit through different mechanisms. Amazon Robotics' mobile units quickly deliver shelves to workers, reducing the distance employees need to travel and speeding up the picking process. This system is particularly effective in environments with high turnover rates and a broad product range.

Conversely, Knapp's shuttle systems excel in high-volume and complex warehouse settings, managing large inventories with precise order fulfillment. According to a McKinsey report, integrating shuttle systems can increase order processing speeds by up to 30%, making them highly suitable for expansive distribution centers.

Cost-effectiveness

Initial implementation costs for Amazon Robotics tend to be lower compared to Knapp, making it a viable option for small to medium-sized warehouses. However, ongoing maintenance and potential floor wear can offset some of these savings over time.

Knapp's shuttle systems, while more expensive upfront, offer better cost-effectiveness in larger warehouses due to their scalability and reduced need for extensive floor modifications. The sophisticated software integration also ensures long-term operational savings through optimized inventory management and reduced error rates.

User-friendliness and Maintenance

Amazon Robotics offers a relatively straightforward deployment and maintenance process, benefiting from Amazon's extensive support infrastructure. The robots' design allows for easy access to components, simplifying routine maintenance tasks.

Knapp's shuttle systems are more complex and require specialized maintenance protocols. Regular inspections and advanced technical support are essential to minimize downtime, which can be a consideration for warehouses operating in high-demand environments.

Key Differences

The primary distinction between Amazon Robotics and Knapp lies in their approach to inventory handling. Amazon Robotics automates the physical movement of inventory shelves to centralized picking stations, optimizing space and reducing worker travel time. In contrast, Knapp employs a shuttle-based system where autonomous carts navigate the warehouse to deliver items directly to workers, offering greater flexibility in inventory placement and retrieval.

Additionally, Amazon Robotics is often favored by e-commerce giants like Amazon for its integration with existing logistics frameworks, whereas Knapp's solutions are preferred by manufacturers and distributors requiring high precision and scalability.

Case Studies: Real-World Applications of Amazon Robotics and Knapp

Amazon Robotics in Action

In Amazon's fulfillment centers, the deployment of Amazon Robotics has led to a 25% reduction in order fulfillment time and a 40% decrease in employee walking distance, as reported in their official statement. This automation has enabled Amazon to handle increased order volumes, especially during peak seasons like holidays, without compromising on efficiency.

Knapp's Shuttle System Implementation

A leading online home furnishings retailer integrated Knapp's shuttle system across its warehouses, resulting in a 35% improvement in order processing times and a 50% reduction in labor costs, according to a Knapp case study. The shuttle system facilitated better inventory management and streamlined the fulfillment process, enhancing overall operational efficiency.

Future Trends in Warehouse Robotics

The future of warehousing is set to be shaped by advancements in robotics and automation. Key trends include:

- Enhanced Interconnectivity: Increased communication and coordination between robots will lead to more sophisticated and efficient warehouse operations.

- AI and Machine Learning Integration: These technologies will enable robots to learn and adapt to dynamic environments, further improving efficiency and accuracy.

- Flexible and Modular Systems: Future robotic solutions will offer more adaptability, allowing warehouses to reconfigure layouts and processes with ease to accommodate varying inventory types and volumes.

- Sustainable Automation: Emphasis on energy-efficient robots will align warehousing operations with sustainability goals.

As these trends materialize, both Amazon Robotics and Knapp are expected to evolve their offerings, integrating more advanced technologies to meet the growing and changing demands of the logistics industry.

Conclusion: Choosing the Right Robotic Solution for Your Warehouse

Deciding between Amazon Robotics and Knapp depends largely on your warehouse's specific needs and scale. For small to medium-sized warehouses seeking cost-effective and efficient automation, Amazon Robotics offers a robust solution with proven results in enhancing productivity. On the other hand, larger warehouses with complex inventory management requirements may find Knapp's shuttle systems to be more suitable due to their scalability and high precision.

Ultimately, it's crucial to assess your warehouse's unique challenges and operational goals to select a robotic system that aligns with your strategic objectives. Staying informed about emerging technologies and maintaining flexibility in your automation strategy will ensure sustained efficiency and competitiveness in the ever-evolving field of warehouse logistics.